About McLube

Since 1954, McLube is a specialist in the development and production of semi-permanent mold release agents for many molding processes, particularly for the Rubber, Composites and Rotomolding industries, as well as anti-adhesive and lubricants, for all types of industries.

Technical features:

- Semi-permanent agents and ready-to-cook resins

- PTFE technology, fluorine chemistry and synthetic resins

- Numerous manufacturing cycles

- Low friction, dry, colourless, non-greasy coating

- No transfer on castings, no interference with finishing and gluing

- Excellent thermal and chemical stability

- Products available in aqueous base or in solvent base

- REACH, RoHS, FDA Compliance

Benefits:

- Improved productivity, reduced cycle times

- Reduced deposits on treated surfaces

- Enhancement of manufacturing tools’ life

- Mold and tool’s protection against corrosion

Materials:

- Elastomers

- Thermoset

- Thermoplastics

- Polyurethanes

Surfaces:

- Metal / Plastic / Ceramic molds

- Press platters

- Flexible chucks / Rigid chucks / Metal rods

- Process tools

Packaging:

- 400 ml aerosol

- Bottles of 5 and 20 litres

- 200 litre drums

Semi-permanent release agents

McLube offers a range of semi-permanent release agents suitable for the various molding processes of Rubber, Composite and Rotational Molding industries.

Technical characteristics and advantages of McLube’s semi-permanent release agents:

- Dry low friction film, colourless and non-greasy

- PTFE technology, fluorine chemistry and synthetic resins

- Lasts many manufacturing cycles before re-application

- Reduction of mold clogging

- No transfer on molded parts

- No interference with finishing and gluing

- Excellent thermal stability

- Products available in aqueous base or in solvent base

Rubber industry

Rubber molding

Semi-permanent release agents and baking resins: two technologies covering various manufacturing processes.

A wide product range suitable for demolding all types of rubbers and vulcanisation systems:

- Classic elastomers: NR, SBR, NBR, CR, EPDM, IIR, CIIR, BIIR

- Special elastomers: FKM, HNBR, ECO, VMQ and FVMQ, CSM, ACM, AEM

Effective for all types of manufacturing processes:

- Injection molding

- Compression molding and compression transfer

Belt manufacturing

Tyre manufacturing

McLube mold release agents provide high-performance solutions for the treatment of tyre molds.

Composite industry

Composite manufacturing

The McLube product line for composites and FRPs (Fiber Reinforced Plastic) is composed of sealers and semi-permanent mold release agents.

These agents are recommended for thermosetting resins, epoxy, polyester and phenolic resins.

They are designed for different types of manufacturing processes:

- Contact molding

- Projection molding

- Vacuum molding

- Filament winding forming

- Resin Transfer Molding (RTM)

- Pultrusion

Manufacture of brake pads

.

Rotational molding

McLube has developed semi-permanent release agents to meet the requirements of rotomolders:

- Suitable for different types of plastics

- Stable at high temperature

- Do not pollute the molded parts

Demandrining agents

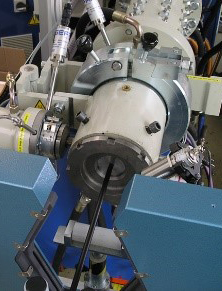

Manufacturing of industrial hoses

McLube designs lubricants and non-stick coatings based on PTFE, fluorinated products and synthetic resins, specially formulated for the processing of mandrels used in various industrial pipe manufacturing processes.

These products make it possible to treat different types of flexible mandrels (EPDM type, PP, PA …), as well as rigid metal mandrels (steel, aluminium, stainless steel, etc.) in order to facilitate their extraction from the pipe after vulcanisation.

These dry agents do not transfer to the pipes and do not interfere with finishing and bonding.

Hose manufacturing

Protection of molds and tools

Corrosion protection

McLube has developed a protective coating of molds and metal parts against storage corrosion, based on PTFE technology, for cold application.

After storage, the molds are reused directly on press without cleaning. The dry PTFE coating serves as a “base-coat”, compatible with a subsequent on-press heat treatment.

Processing of extrusion tools

Anti-tack, Low coefficient of friction and

lubricants

Anti-tack processing aids

Treatment of uncured hoses before open steam or pan curing

The created film is colourless, steam resistant, and avoids the sticking of rubber parts during autoclave vulcanisation on trays.

Treatment of blanks before compression moulding

The treatment of raw rubber blanks with McLube products provides effective and colourless anti-stick coatings that improve material creep and air evacuation during molding

Low coefficient of friction

Rubber finished parts processing

McLube has developed agents that allow dry and durable processing on finished parts to reduce friction coefficients:

- Persistent treatment of friction parts

- Improvement of the sliding of joints mounted in automatic, …

Assembly and Insertion Aids for rubber and plastic parts

McLube mounting aid lubricants are designed to facilitate mounting of rubber or plastic profiles and parts to reduce stress in the workpiece.

Surface treatment of any kind

All metal surfaces, wood, rubber, plastics can be treated with McLube technology to reduce friction coefficients.

Lubricants

Lubricants for pianos

McLube Piano lubricants provide low friction and excellent lubrication characteristics for use in piano tuning and maintenance.

The dry, colourless lubricant coating can handle all types of keyboard tips (recess and pendulum), capstans, lever and return springs as well as different joints.

Their specific formulation also prevents corrosion and discoloration of piano strings and all other metal parts of the piano.

Oven chain lubricant and high temperature bearings

McLube MoS2 is a lubricant suitable for high temperature use on oven chains, conveyors or bearings, to protect against wear, rust and corrosion.

Based on molybdenum disulphide, it does not carbonise, smoke or give off odours during use at high temperatures. McLube MoS2 offers excellent lubrication and a low friction coefficient.

Applications include steel mills, bakery ovens, oven trolleys, paint drying … The product is extremely useful in dirty and corrosive environments.